Founder Story

- Share

1、Bear Family Mission from Childhood

I am Fang Zhimin, president of Taizhou Dingfeng Electric Appliance Co., Ltd, I was born in 1986 in a small village in Wenling city, Zhejiang province. In 1989, my father, Mr Fang Zhengpu, with deposit saved during 10-year experience of selling glasses in northeast China, founded Wenling Shanshi Capacitor Manufactory (later renamed Taizhou Dingfeng Electric Appliance Co., Ltd.), which was the earliest enterprise engaged in the research and development of capacitor in Wenling. Now Wenling has become one of the water pump and motor production centers in China and even all around the world.

From preliminary to high school, my parents were busy dealing with company affairs and I was used to living in the city on my own to study. Though born in a entrepreneur's family, I didn't get into the habit of relying on my parents, instead I learned independence and self-improvement. In winter and summer vacation, I would go to factory to help my parents, from that I understood the hard work of my parents, and gradually an idea germinated in my mind: helping my parents revitalize the enterprise. Having graduated from high school, at the request of family business, I was arranged to study abroad, there were two choices in front of me: one was to go to England, another was to go to Japan. In everybody's opinion, British were much better than Japan, so they thought that I should go to England, but I was determined to go to Japan though confronted with others’ question.

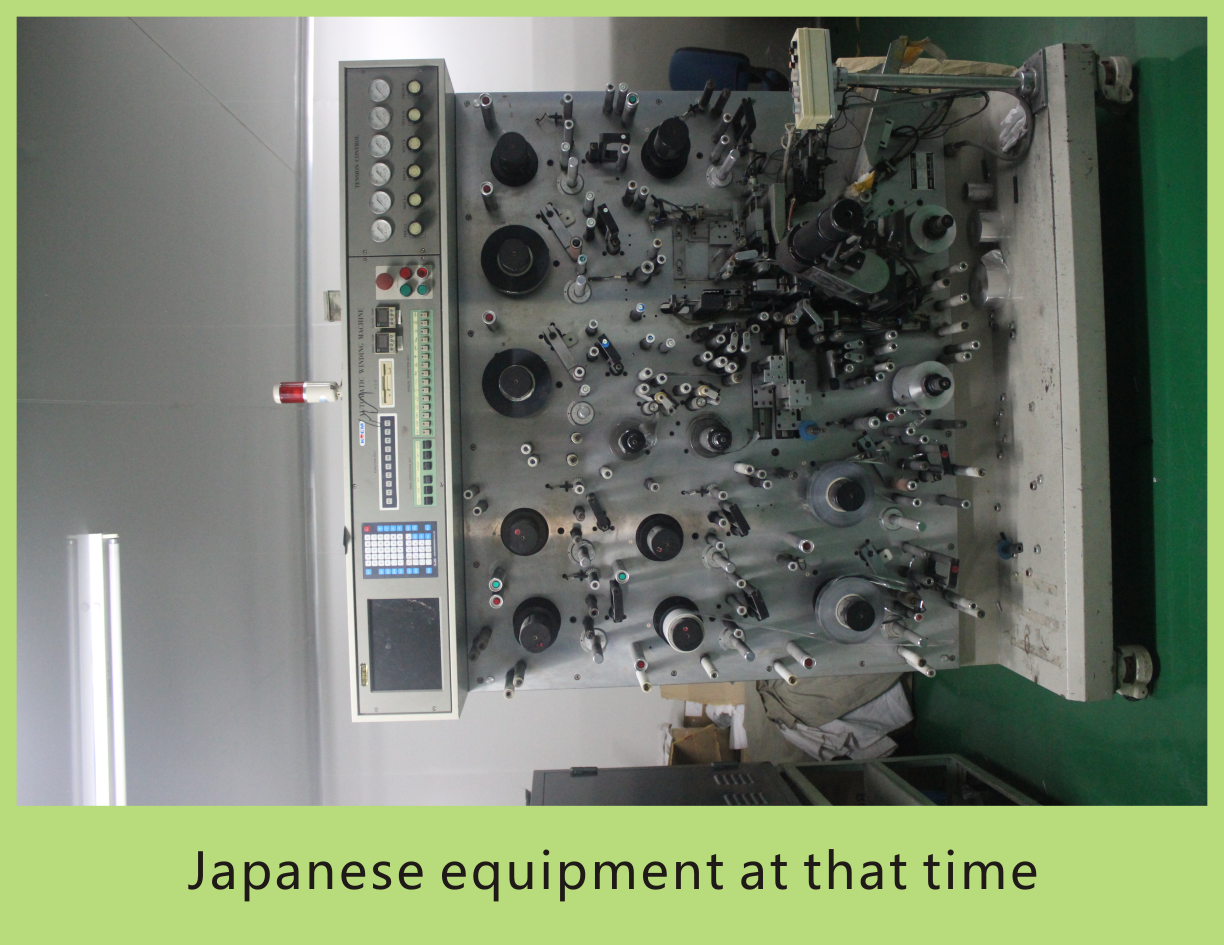

I told my father the reason of choosing Japan. When I was in my high school,, because of expansion and development of capacitor manufactory, my father imported a high-end automatic winding equipment from Japan. When the equipment arrived in our factory, Japan's two engineers also accompanied to guide us how to install and operate the machine. This was a big deal of our factory, because this was our company's first fully automatic equipment. I didn't know what equipment looked like, and I was very curious, so every day I was following my father and Japanese engineers, and this was my first contact with foreigners. This week contact let me realize two things: first, Japanese focus to the work and the technical skill of Japanese equipments; second, I had an illusion: the most developed place of capacitor industry was Japan. Perhaps going to Japan could gain more benefit for the long-term development of the enterprise, so I finally was determined to go to Japanese.

2、Go Deep into Japanese Capacitor Industry

In the first year to Japan, our school arranged us to learning language. In order to adapt to this country as soon as possible, I studied hard every day. Soon a year passed, and I successfully passed the examination and entered the Japanese Reitaku University (International business major). I thought I could concentrate my minds on learning management theory, but at the end of my first year of college, due to the several side investments, the capacitor sales fell sharply under many prominent enterprises’ competition, eventually leading to capital chain tension. Back home that year, my father told me I had to find a way to solve my maintenance fee, this was the first time I saw my father cry.

That night, I realized that now that coming to Japan, I should not only learn the knowledge in books, but also should go out and learn more practical thing and by the way earn living expenses. After returning to Japan, I started work-study program. Because of the solid language foundation in the first year plus and later hardworking, I got a scholarship from school every year, and at the same time I also started my long practice in Japanese enterprises. In line with the industry has always been to Japan capacitance sacred yearning, at first I searched some information on the Internet about Japan capacitor manufacturer, I also paid close attention to the information on hiring temporary workers at any time. Under the constant efforts, I was employed by one of the enterprises. High-end and dust-free workshop, tidy and standard material tools, production process of assembly line, complete testing equipment and research and development laboratories, these were my first image of Japan capacitor factory.

I worked as a pipelining worker, although I was a temporary worker working two days a week, but I received the strict training before production. There was an old staff teaching us, each product we manufactured would be checked and older employees would share responsibility with us. if there was a product unqualified, the whole batch would not be allowed to sell, this kind of management system impressed me so much. Although both belonged to capacitor factory, I haven't seen many products in Japan, their research and development team was very strong, what made me impress most was the same type of products, their volume were smaller than our products, really realizing the idea of small volume while large capacity. This paragraph of time work experience makes me realize, the strength of Japan's enterprises lied in their corporate culture and development ability of core technology. From this time, I began to reflect on the future of the family business.

3、Quality Management and Marketing Reform

In 2009, I graduated a year in advance, returning to my own business, I studied the status quo of the current enterprise, summing up the five points:

1: Complicated production process;

2: Poor quality of employees;

3: Chaotic production;

4: Lacking experiment equipment;

5: Failure to form a quality system.

This may have product quality difficult to achieve standardization, and we also often received customers’ complaints about product damage in the process of long-term use. I was determined to change all of these problems. Having seen the Japanese enterprise, I understood that quality counted most. So I reorganized the production process, bought a large number of experimental equipments and set up the quality department. Under a series of reform, the quality of our products was up a notch obviously. Before, we knew our product quality only by clients’ feedback. Now because we adopted selective examination of sampling aging experiment, our product qualified rate reached 99.9%, truly eliminating the customer doubts about our product quality.

From 2012, our enterprise moved towards prosperity again. In that year, my father had me take over the whole enterprise, thus I became the chairman of Taizhou Dingfeng Electric Appliance Co., Ltd. Since then, the burden in my shoulder was heavier, during a few years I had successfully built sales, production, quality, technology, finance teams. At that time I have been thinking that, even though our export business was not bad, our customers were also very satisfied about the quality of our products. Although there were many orders, most of the customers were distributors, mostly engaged in product maintenance, we lacked supporting services with real foreign pump manufacturers. If we seldom cooperate with these factories, we would find it difficult to fundamentally improve our strength, making your own brand a well-known brand in capacitor manufacturing field.

4、Strict Attitude + R&D + Innovation = Furture

That year I asked the ministry of foreign trade to redesign the key development plan, through continuous diligence, we finally reached business relationship with a Germany capacitor manufacturers. They themselves also manufactured capacitor, due to various reasons such as limited capacity, they have been considering doing OEM in China. After a long period of contact with us and several visits to our factory, they finally chose us. Customer was very rigorous about the choice of the manufacturer, earlier they would send people to supervise the production and shipment. In the first or second order trial, the customer put forward a lot of problems. Because they were professional capacitor manufacturers, our products cannot be sold directly but rather a long time performance test experiment according to their requirements, they have given us two opportunities to improve. In view of the customer's questions, we immediately organized meeting to rectify, from small orders to a batch of large cargo, from each inspection supervision to an annual inspection supervision, through years of efforts, we have finally been approved because our product of each batch was qualified.

Gradually, we have reached business relationship with some well-known water pump manufacturers in Turkey, India and even Germany, Italy. During the cooperation with some foreign water pump manufacturers over the years, customers have given us a lot of advice. The most important was that now some consumers were in favor of water pump of small volume so manufacturers were making efforts to reduce the volume of capacitor with no influence on quality. This was a new problem for us, cause smaller volume means thinner raw materials while thinner film were not able to withstand high voltage. Currently, our team are thinking over solution to solve this problem, determined to break through the barrier by double coating film technology. I believe that more than half year we will be able to overcome the technical problem, to meet customer requirements. I realize that business success lies in the continuous improvement, self awareness of my own shortcomings and lies in the unremitting efforts of a team.

5、Corporate Personality Counts Most

We have built cooperation with more than 1000 clients from over 50 countries in recent years, making us realize that doing business is to be a person. Actually the ideas of foreign customers and our Chinese are similar, they pay more attention to the enterprise boss's character in the premise of the same quality. In 2015, a negotiation with a customer to factory made me have a deep impression.

That was an Iranian customer, it was the first time for them to come to China. They came with a cabinet order, having inspected no less than 10 capacitor manufactories, although in their opinion, our equipment and production technology were the best of so many factories, our price was not the cheapest. They have not made decision about which to purchase, they planned to discuss after returning to Iran. At the end of visiting China, they went to Shanghai by train from Wenling, their flight was on the second night. Because of so many days’ hard work in China, they fell asleep in motor car, and accidentally forgot their bag in motor car, inside the package are all of their cash, credit cards and passports, they were very urgent and didn’t know what to do, so they made a call to me. Hearing this, I was also very worried about them because they cannot communicate in Chinese. I immediately decided to drive to Shanghai to meet with them, that night I helped them contact the police and arrange accommodation. Under the continuous efforts, the package was found but cannot be gained until the next day. At noon the next day we successfully got the lost package, thus customers returned to Iran smoothly. They were so moved, after back soon, we received the order from him and now we are good friends. This matter tells us the importance of a corporate personality.

6、Do Not Seek Big but Delicate, Cast Century-old Capacitor

Through the efforts of two generation, Dingfeng has become a well-known brand in domestic capacitor manufacturing field. We are making efforts, but it is not enough. In a training class, I heard that among Germany companies, there are 3000 companies with excellent quality although possessing not big production value. I think Dingfeng is the same, it does not matter how many products it manufactures, how big production value it possesses, I hope Dingfeng could be fine and strong, just as German companies. Though enterprises are small, making Dingfeng top one in capacitor manufacturing field, this is my dream. May be I cannot achieve this dream in my life but now as a father of two, I hope we can pass our family spirit, making century’s standing enterprise and casting magnificent passage of one hundred years